COMPANY

Founded in 1982 in Umbria, Italy, by the passion for mechanics and the entrepreneurial spirit of Pietro Flavi, FOMAP has operated since its inception in the field of precision engineering for the Defense and Energy sectors.

Thanks to collaborations with major international companies in the industry, the company has gained extensive experience in problem-solving, specializing in the production of medium and large-sized components based on customer drawings, with high-precision CNC boring, drilling, milling, and turning operations.

Over the years, FOMAP has developed its own engineering expertise and, today, under the leadership of the third generation, it is capable of co-designing and manufacturing in Italy customized Build to Print and Build to Spec solutions, as well as managing projects with system responsibility for the Aerospace, Space, Defense (AS&D), and Energy sectors.

Precision serving power

FOMAP specializes in high-precision machining for stator components used in the turbogas sector. Leveraging a state-of-the-art CNC machine park, extensive expertise, and rigorously controlled processes, we deliver complex machining operations on high-performance materials, ensuring tight tolerances, excellent surface finishes, and full traceability.

We collaborate with leading OEMs and Tier 1 suppliers in the sector, providing reliable solutions for the production of stator casings, rings, diaphragms, inlet cases, and bearing supports. Our capabilities include complete vertical process management, from rough machining to finishing, including dimensional inspections, qualified welding processes, heat treatments, and assembly.

Strategic partner for the production of high-reliability aeronautical systems and components We manufacture components for aircraft engines — such as stators — and structural parts for nacelles and reverse thrust systems, using special alloys of steel, Inconel, aluminum, and titanium. We work with extremely tight tolerances to ensure consistent performance and maximum operational reliability.

The components are produced to customer specifications and follow planned and documented inspection and verification processes, including First Article Inspection (FAI).

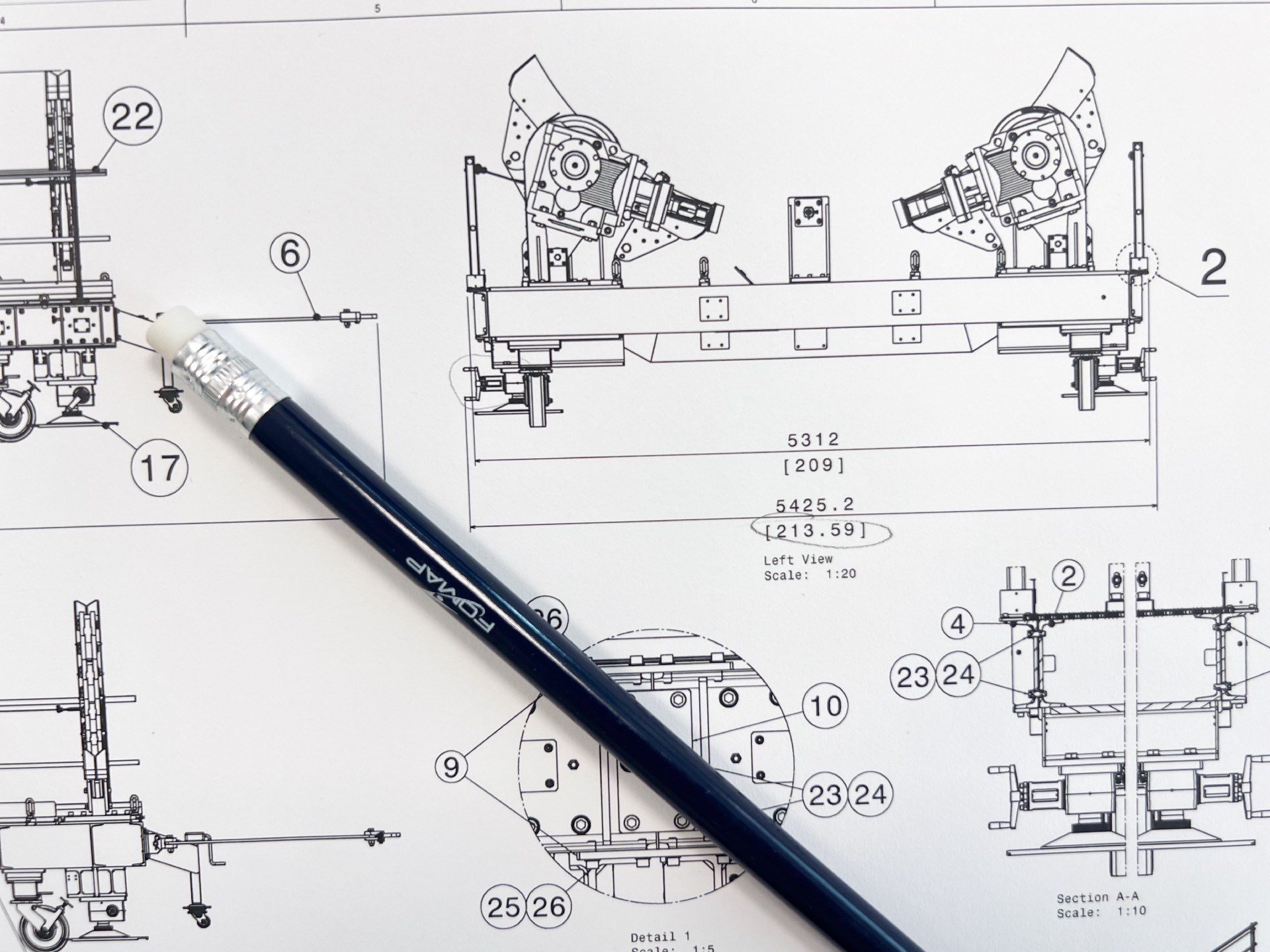

In the aeronautics sector, we also manufacture, on customer specification (Build to Spec), MGSE structures — such as stands and support equipment — for aircraft construction and maintenance. Every supply includes the complete technical documentation, user and maintenance manuals, and compliance with CE regulations.

Integrated capabilities for complex missions We design and manufacture precision mechanical systems and components for the defense sector, ensuring the highest standards of reliability, quality, and safety at every stage of the production cycle. We apply our technology in the land and naval sectors, particularly in radar, anti-drone, and submarine systems. Year after year, in these fields, we have earned a reputation as reliable partners for leading companies in the industry. Thanks to our advanced machinery, highly qualified personnel, and rigorous production processes, we deliver top performance even in the most critical applications. We manage all special processes internally and through qualified supply chains, offering our customers the convenience of an integrated supply under a single purchase order (single PO). We are ISO 9001 and EN 9100 certified for quality, compliant with Art. 18 for the defense industry, and operate in full adherence to the highest industry standards.

Precision on Earth. Reliability in Orbit.

We are trusted partners in the major space programs of international clients, building ultra-high-precision mechanical systems and components for both satellite constellations and exploration missions.

We operate in controlled environments, using special materials and advanced technologies to ensure peak performance when there is no room for error.

The programs we have participated in rank among the most significant in the Western world, contributing to projects developed for ESA and NASA by industry leaders.

We manufacture flight subassemblies for satellites and spacecraft, and we design and produce MGSE (Mechanical Ground Support Equipment) and customized transport containers developed according to customer specifications (SOW). We follow a structured process that begins with the KOM (Kick-Off Meeting) and concludes with the delivery of the complete system, including validation testing, technical documentation, and CE-compliant certification.

Our ISO 9001 and EN 9100 certifications attest to our unwavering commitment to absolute quality and compliance with the most stringent aerospace standards.

Engineering

Our highly qualified team develops build-to-print and build-to-spec

solutions, with advanced expertise in the design of complex assemblies and

technical project management.

Manufacturing

We have an advanced CNC machine park and specialized personnel, ensuring high quality and repeatability even for complex geometries and tight tolerances.

Special Processes

All special processes are carried out internally and with our supply chain in accordance with stringent standards and recognized qualifications, ensuring full compliance with the demanding requirements of the most critical sectors.

Assembly and Integration

We perform assembly and testing of mechanical and electromechanical groups and subsystems, including the production of MGSE and complex equipment. We conduct functional tests, proof tests, and inspections

according to customer specifications, guaranteeing full compliance for both prototype and series production.

Work with us

We are looking for passionate, skilled, and motivated individuals ready to contribute to the growth of an ambitious, excellence-driven organization. Joining our team means embracing core values such as innovation, responsibility, and collaboration, within a dynamic and highly professional environment.

If you're eager to challenge yourself, develop new skills, and make a real impact every day, we encourage you to submit a spontaneous application: you might be exactly the talent we’re looking for.